Resource recovery plan

Application area

Taizhupu International's technology has undergone over 50 years of testing and inspection, and has been applied to over 90 projects in different fields worldwide. The experience and diversity of plasma technology possessed by Taizhupu International can help customers cope with their different resource recovery issues.

- Recovery of base metals

- Steelmaking waste (such as arc furnace dust)

- Recycling of precious metals

- Recycling of precious metals

- Waste catalysts (such as industrial catalysts)

- Mining waste

We have confidence in Tai Zhupu International's plasma solution, which has stronger technical recovery capabilities compared to other competing technology plasma solutions.

Solar Applied Materials Technology Company& nbsp; Chief Operating Officer

Electronic waste

Recycling precious metals from electronic waste

Electronic waste includes waste electronic and electrical equipment from household, commercial, and industrial sources. These garbage contain multiple hazardous components, which can pose a threat to human health if left untreated or improperly disposed of. In the past few decades, the electronics industry has indeed changed the world, and electronic products are now ubiquitous in daily life. The demand for electronic products is constantly growing, and the resulting waste is also increasing. According to statistics from the United Nations Environment Programme, the total amount of electronic waste worldwide each year reaches 50 million tons.

The new plasma technology developed by Taizhupu International can solve the growing problem of electronic waste. This technology can separate valuable resources from electronic waste while destroying harmful components. By adopting this process, companies no longer have to bear the increasing costs of extracting metals, while also promoting their contribution to the protection of natural resources.

Please contact Taizhupu International Company and let us assist you in handling electronic waste.

Through firsthand experience, we trust Taizhupu International Company and their DC plasma arc technology.

Hacks Metals and Minerals -- vice president

Abandoned catalysts

Recovery of Platinum Group Metals from CatalystsThe technology application of Taizhupu International Company can be used to recover platinum, palladium, and rhodium from waste containing precious metals. After decades of practice, its recovery rate has always held a leading position. This technology has been patented and its main advantage lies not only in its best technical recycling performance and operational flexibility, but also in its minimal environmental impact and very low cost base

Catalyst waste includes automotive catalysts and industrial catalysts (such as catalysts from the chemical and petrochemical industries), which contain precious metals and platinum group metals. This type of metal has unique properties, scarce reserves, and the process of extracting from primary sources is very complex, all of which make it a very valuable resource

The plasma waste recycling process developed by Taizhupu International Company separates precious metals and other low value catalyst substances through melting. At the same time, these low value catalyst materials are made into a safe and reusable glass body. We call this product ionic rock and it has obtained relevant approval. This technology can also destroy harmful organic components such as dioxins contained in waste

Please contact Taizhupu International Company for assistance in handling catalyst waste

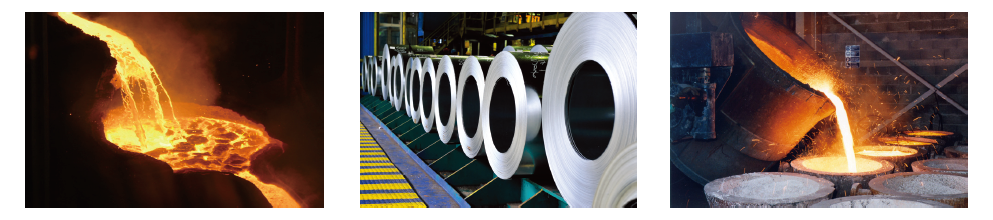

Steelmaking waste

Recovery of Ordinary Metals from Electric Arc Furnace DustTaizhupu International Company has rich experience in handling steelmaking waste, as well as other industrial and household waste containing ordinary metals. Essentially, plasma technology is used to recover valuable components from waste that is considered worthless and sent to landfill or compost. After using plasma technology, there is no need for landfilling, and valuable metals such as iron, nickel, chromium, and molybdenum can be recovered from steelmaking waste to achieve maximum benefits

Given environmental requirements and the particulate dust form of steelmaking waste itself, it is very difficult to recycle steelmaking waste using the initial steelmaking equipment. This requires finding a feasible solution to separate valuable and recyclable metals and other harmful components for reuse or resale

Taizhupu International's plasma technology provides the best solution for the treatment of steelmaking waste by adopting an environmentally friendly and sustainable method that not only extracts valuable substances from the waste, but also eliminates harmful components from the waste. Please contact Taizhupu International Company and let us assist you in handling steelmaking waste

After adopting the advanced technology of Taizhupu International Company, one of our clients has recovered approximately $190 million worth of materials and reduced the amount of hazardous waste landfill by several hundred thousand tons in the 20 years of factory operation

Mining waste

Recycling precious metals from tailings

Taizhupu International Company can provide metal recycling systems for recovering valuable substances from various difficult to dispose powder or granular mining waste. In the past 30 years, plasma companies have treated such wastes, including chromite, basalt, ores containing platinum group elements, ilmenite and quartz mining wastes.

Many harmful substances contained in mining waste can cause great harm to the local ecosystem, but mining waste also contains some valuable components, such as precious metals. The increasingly strict environmental protection system, rising prices, and decreasing reserves of precious metals have all prompted people to consider the recycling and utilization of tailings. However, the accompanying environmental and technological issues have always made the recycling and reuse of such waste lack economic feasibility.

The patented DC arc technology of Taizhupu International Company provides the possibility for this resource recycling, which not only allows for the disposal and destruction of hazardous components in waste, but also allows for the extraction of valuable components from mining waste through further extraction.

Please contact Taizhupu International Company for assistance in handling mining waste.

Given the experience and successful performance of Taizhupu International in plasma technology, we believe that Taizhupu International is our most suitable technology partner.

Mitsubishi Corporation Petroleum coke department

In order to create greater value for our customers, we insist on continuously investing in independent research and development of cutting-edge and high-end technologies such as energy, chemical, environmental protection, and new materials. We also collaborate with excellent professional institutions to leverage the advantages of Poma Environment in management, mechanism, and funding, and conduct more technological transformations.

Address: No. 168 Pugong Road, Shanghai Chemical Industry Zone, China

Customer service hotline: 021-60742899

website: www.cpglct.cn

©2023 Copyright Puma (Shanghai) Environmental Technology Co., Ltd