Fly ash recovery plan

Fly ash treatment plan

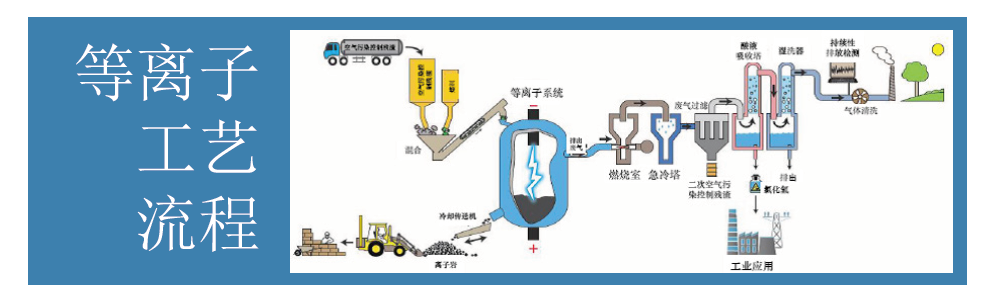

Clean plasma arc technology: High temperature plasma arc serves as a power and functional heat source, combining the chemical inert heat of plasma arc with the traditional stability and controllability of gas flame. Taizhupu International uses a plasma arc heat source to melt, gasify, or evaporate fly ash, which is then processed, recycled, and created into useful commodities.

-

Convert fly ash into two products (see page 6):

- Building aggregate, glass body: approved by the Environmental Protection Agency, harmless material, highly impermeable

- Hydrochloric acid: as a product that can be recycled and resold

- It is a fly ash treatment scheme that has been operated and validated in the market

- The environmental protection and sustainability of this technology are both first-class

- It is a zero emission treatment plan for fly ash

For fly ash, plasma is the most feasible and flexible recycling system.

Green Energy Park Technical Director

fly ash

Challenges brought by fly ash

With the increase in waste energy utilization, fly ash is also increasing significantly. Due to its extremely high alkalinity, as well as a large amount of volatile heavy metals, dioxins, furans, chlorine, and highly soluble salts, this hazardous waste poses a great challenge to our environment. It is imperative to find a safe handling method. The new EU regulations have reduced the current and future landfill volume, leading to rising taxes and costs. These factors, coupled with the increasingly prominent corporate social responsibility, have attracted great attention to the plasma vitrification technology of Taizhupu International Company. This technology can achieve the transformation from waste disposal plans to resource recovery plans, gradually moving towards the top of the waste management hierarchy

We have personally experienced that we trust Taizhupu International Company and their DC plasma arc technology.

Hasco Group

Vice President - Global Solutions

technology

Technical solution for disposal of fly ash by Taizhupu International CompanyClean plasma technology can completely remove harmful properties from fly ash, converting the vast majority of substances in the feed into useful by-products for resale or reuse, thereby comprehensively improving the environmental performance of waste to energy conversion facilities. Over time, the toxicity of fly ash will become higher in concentration and more hazardous. When this situation occurs, it will pose a great challenge for many other traditional treatment processes, but it will not affect plasma technology. This characteristic enables the technology to withstand the test of time, cope with potential changes in taxes, garbage disposal fees, and policies, and avoid major commercial risks

In many cases, combining plasma technology with waste to energy conversion projects can significantly reduce the potential risk of hazardous waste emissions, reduce operating costs, and have a positive impact on obtaining planning permits. With the continuous development of this field and the increasingly strict environmental policies, it is foreseeable that more and more air purification projects will adopt plasma technology in the coming years. The integration of plasma technology and modern waste to energy conversion technology can eliminate all secondary hazardous waste and comprehensively improve environmental performance. Plasma technology will become a fundamental component of future waste treatment infrastructure

Handling capacity and joint resettlement

The treatment capacity of plasma facilities and the benefits of joint placement with waste to energy conversion facilitiesA standard plasma fly ash treatment system can process approximately 30000 – 50000 tons of waste annually. The entire system occupies a small area and can be installed and configured together with new or existing waste to energy conversion facilities. This allows for the disposal of waste from its source, shortening the transportation distance and reducing emissions. Adopting this method can significantly reduce the declared amount of hazardous waste, eliminating the need for twice processing of waste and strict supervision of hazardous waste transportation. The joint installation of plasma systems next to waste to energy conversion facilities can bring the following benefits:

- Local power supply

- Start disposal at the source/facilitate on-site disposal

- Shorten transportation distance

- Electricity with lower carbon emission reduction factors generated by waste to energy conversion facilities can be used

Product

Plasma technology transforms fly ash into two products:

- Vitreous body: Vitreous body is a type of glass that has been approved by the UK Environment Agency and can be widely used in the construction and ceramic industries. The waste that constitutes the glass body can account for 70-80% of the total amount of waste treated by incineration plants or other waste heat treatment facilities. Vitreous bodies are recognized as a usable product rather than waste, which greatly increases the revenue generating potential of plasma technology.

- Hydrochloric acid: In plasma technology, chlorine in the exhaust gas is collected to produce hydrochloric acid. This process not only brings a saleable product, but also avoids generating a large amount of secondary waste, saving related waste treatment costs

Please contact Taizhupu International Company for assistance in handling fly ash.

Given the experience of Taizhupu International and their successful performance in plasma technology, we believe that Taizhupu International is our most suitable technology partner

Petroleum coke Department of Mitsubishi Corporation

In order to create greater value for our customers, we insist on continuously investing in independent research and development of cutting-edge and high-end technologies such as energy, chemical, environmental protection, and new materials. We also collaborate with excellent professional institutions to leverage the advantages of Poma Environment in management, mechanism, and funding, and conduct more technological transformations.

Address: No. 168 Pugong Road, Shanghai Chemical Industry Zone, China

Customer service hotline: 021-60742899

website: www.cpglct.cn

©2023 Copyright Puma (Shanghai) Environmental Technology Co., Ltd